I went back to McMurdo on December 1 to post journals and returned to Beacon Valley field camp on December 3, 2008 in time for a drill site move. Dave and the team decided to abandon the hole at Site #3 after drilling to 16.05 m and hitting dirty ice. They selected a new drilling location (Site 4) approximately ½ mile south of site #3. The team must dismantle the drill at the current location and prepare for the helicopter supported move to the next drill location by 2000 hours.

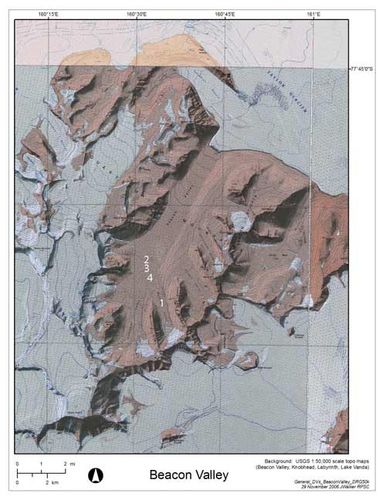

Base map provided by J Walker RPSC 29 November 2006.

Base map provided by J Walker RPSC 29 November 2006.

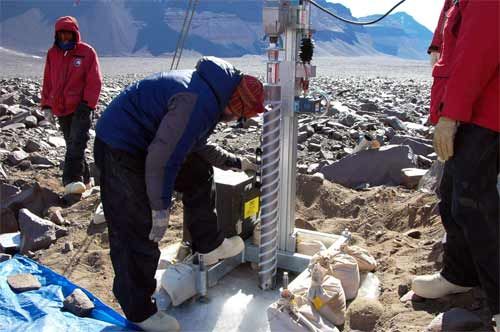

Tanner Kuhl, (standing in blue jacket) driller, contemplates abandoning site 3.

Tanner Kuhl, (standing in blue jacket) driller, contemplates abandoning site 3.

This is the hole at Site 3.

This is the hole at Site 3.

Dave looks down hole at site #3.

Dave looks down hole at site #3.

The heavy equipment is put in a net sling that is clipped to the helicopter by Sean. The helicopter lifts the sling and takes it to the next drilling site. You can view the following video to see the helicopter move.

http://

On December 4, the team staged the new location to resume drilling at Site 4.

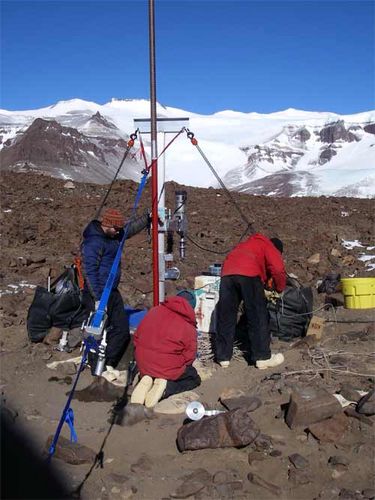

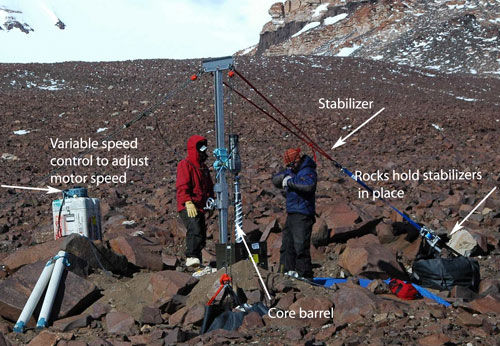

Joe (left) and Tanner (right) set up the drill at the new location.

Joe (left) and Tanner (right) set up the drill at the new location.

The stabilizers are held in place with large rocks.

The stabilizers are held in place with large rocks.

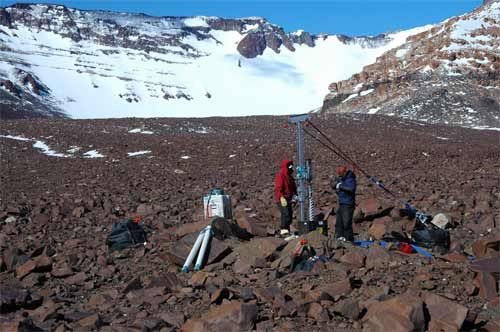

Tanner measures to make sure that the drilling starts on level ground.

Tanner measures to make sure that the drilling starts on level ground.

The tarp is placed on the ground so that sediment does not blow into the hole.

The tarp is placed on the ground so that sediment does not blow into the hole.

This photograph shows a freshly cut ice core.

This photograph shows a freshly cut ice core.

Most of the cores were retrieved in one piece, but this is not always the case. The video below shows a core retrieved with one crack. The largest section is usable for gas analysis.

http://

This 50 cm section of ice core was retrieved in tact.

This 50 cm section of ice core was retrieved in tact.

This core shows well formed gas bubbles.

This core shows well formed gas bubbles.

The move to the new drilling location proved to be a good move, and 7 m of clean ice were retrieved on the first day of drilling.

Since this journal is all about drilling, this is a good time to profile the driller, Tanner Kuhl.

Tanner Kuhl is an engineer and works for ICDS (Ice Coring and Drilling Services) in Madison, Wisconsin. ICDS is the National Science Foundation (NSF) contractor for drilling in Antarctica. Other companies and institutions also drill in Antarctica depending on the medium. Tanner's "regular" job is working for ICDS in Madison, WI on the engineering side of drill development, but he has been spectacular in the field. Although Tanner has a degree in engineering, most of the drillers with ICDS do not have engineering degrees. According to Tanner, the skills needed for the job are a good mechanical knowledge and resourcefulness. In addition, drillers must be outdoors enthusiasts. I would add that to work in Antarctica the drillers should be extreme weather outdoor enthusiasts.

Tanner answered questions about the design and operation of the drill.

Question: How is this drill different from a conventional drill?

Tanner: The drill is a rotary drill mounted on a drill press tower. The drill itself is portable and weighs less than 2,000 lbs so that it can be moved by helicopter. It also can be moved manually for short distances. The drill looks different because it is a specialized drill specifically developed for the challenges associated with drilling through the ice in Beacon Valley. The main challenge is that the drill has to incorporate two different technologies required to drill through both ice and rock. Also, the material encountered in the hole constantly changes with depth. These challenges must be addressed without using drilling fluid, which is not permitted in the Dry Valleys.

Question: What modifications did you have to make to the drill as you encountered problems?

Tanner: I tried various drill feed and rotations speeds, varied the depth of core drilled on each run and core retrieval schemes. I also made repairs to drill heads and core barrels as they sustained damage.

Question: What future modifications are necessary to successfully drill in Beacon Valley?

Tanner: Modifications that make the cutter head and core barrel stronger would be beneficial. Also, different core retrieval methods need to be explored. Finally, technology needs to be explored that will allow the drill to penetrate ice cement more efficiently.

In summary, Tanner says that the ideal drill for Antarctica should meet the following criteria:

Drill effectively through rock and ice

Provide enough mobility to be moved manually for short distances

Meet the environmental quality issues for the Dry Valleys

Retrieve reasonable quality core for science projects.

Here is a photo illustrating the key parts of the drilling operation.

The major parts of the drill and components of the operation are labeled.

The major parts of the drill and components of the operation are labeled.