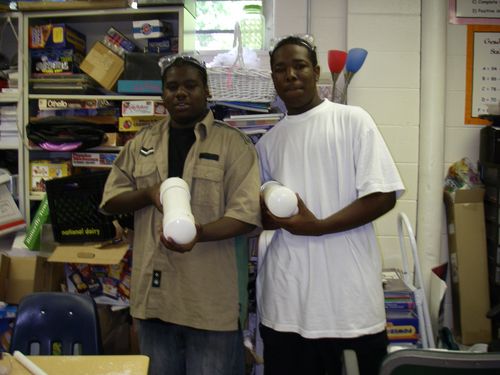

Our underwater ROV is continuing to blossom and grow. The process is a bit complicated but we are seeing the results of our hard work. The students are working on several parts of the process at one time. An important element of the finished product will be the floatation devices. We measured the inside length of the frame and then took a piece of three (3) inch PVC pipe and cut two pieces that are ½ inch shorter than the length of the inside of the frame. The students then sanded the ends of the PVC pipe pieces.

The large PVC pipe will be used to make floatation devices for the underwater ROV.

The large PVC pipe will be used to make floatation devices for the underwater ROV.

The next step was to attach PVC end caps to each end of the cut PVC pipe pieces.

The flotation device consists of a piece of three inch PVC pipe with an end cap on each end.

The flotation device consists of a piece of three inch PVC pipe with an end cap on each end.

We then checked to see if the finished floatation devices would fit inside the frame. They did!

The two floatation devices fit perfectly inside the frame of the underwater ROV.

The two floatation devices fit perfectly inside the frame of the underwater ROV.

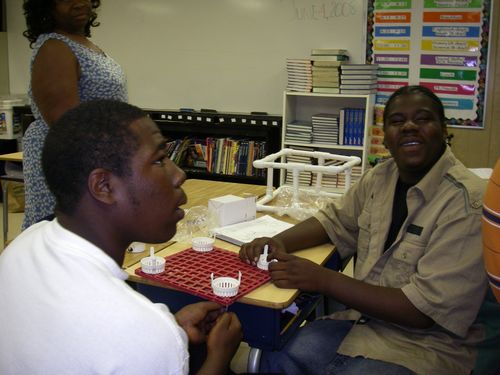

Another important element of the underwater ROV is the pump system. The pumps we are using are 500 gallon per hour bilge pumps. We needed a base to attach the pumps to so we took a plastic milk crate and cut out the bottom. Mr. Tice, a Teaching Assistant, jumped right in and helped Michael and DeQuires use a hand saw to cut out the bottom of a plastic milk crate.

The bottom of a plastic milk crate is cut out with a hand saw to create a base for the underwater ROV.

The bottom of a plastic milk crate is cut out with a hand saw to create a base for the underwater ROV.

Then we used plastic ties to attach a pump to each of the four corners of the piece of plastic milk crate.

The four 500 gallon per hour bilge pumps are attached to the base using plastic ties.

The four 500 gallon per hour bilge pumps are attached to the base using plastic ties.

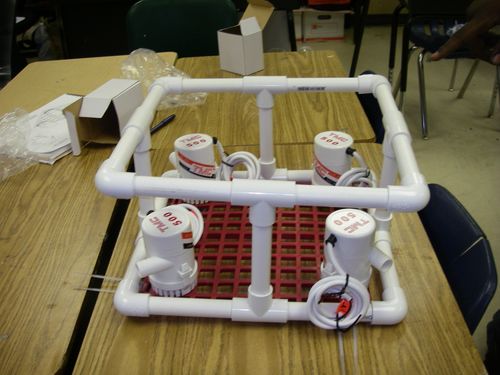

The finished product is a work of art.

The base has a bilge pump attached to each of the four corners using plastic ties.

The base has a bilge pump attached to each of the four corners using plastic ties.

Of course, it won't do any good if the plastic base with the pumps doesn't fit inside the frame. Luckily, it does (Did you notice which frame we selected? Was it the one you thought we would select?)

The base with four of the bilge pumps fits perfectly inside the frame.

The base with four of the bilge pumps fits perfectly inside the frame.

You will notice that there are four pumps attached. However, we need six pumps for the underwater ROV to function properly. The final two pumps will need to be attached in a way that works with the existing four and yet still fits inside the frame. Do you know how we plan to do it?

Unfortunately, you will have to wait a few months to find out the solution to this problem. School is almost over and summer break starts in just a few days. The original plan was to finish constructing the underwater ROV during summer school but sometimes things don't work out the way we plan. I am teaching first, second, and third graders for summer school and the plans are written for upper elementary and middle school students. The new plan is to finish the underwater ROV in September, test it in the field in October, and then take it to Antarctica in November.

We did decide on a name for our underwater ROV because we got tired of calling it "the underwater ROV". The name we selected was S.A.R.A. for SECEP's Aquatic Robotic Apparatus. We understand that everything in Antarctica has an acronym so it seemed fitting that our underwater ROV should also. Hope you like the name we chose and that you'll check back in September to see how she turns out.