News Update

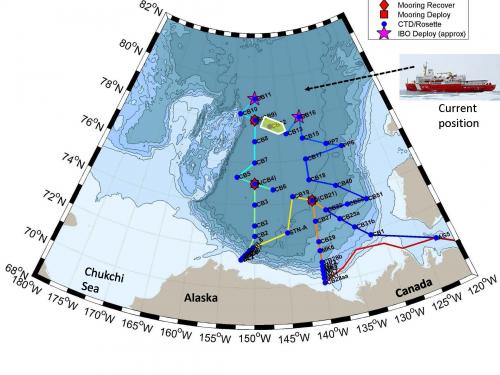

Present location of the CCGS Louis S. St-Laurent.

Present location of the CCGS Louis S. St-Laurent.

The past three days have been mostly dedicated to "ice ops" and the deployment of the ITPs and Ice Mass Balance Buoys (IMBs). Today is the first of several days of "mooring ops" and basically ITP/IMB deployment was the warm-up for the mooring deployments. Everything about the mooring station is bigger – much bigger. The buoy for an ITP is a styrofoam cone about 3 feet in diameter and weighs less than a hundred pounds. The buoy for a mooring is metal sphere about 5 1/2 feet in diameter and weighs about 2500 pounds. The cable for the ITP is about 800 meters long (1/2 a mile) and the cable for the mooring is about 3800 meters long (2 1/2 miles). The anchor weights for the ITP is about 280 pounds and the anchor weights for the mooring comes to about 4500 pounds. There are three sensors on the ITPs which we deployed this year (pressure, conductivity and temperature) and there are at least 8 sensors on the mooring stations. Installation time for an ITP is about 3 hours, and the recovery and redeployment of the mooring takes about 24 hours.

Mooring Operations

Mooring ops is a fairly long drawn out operation since there is both a recovery and a redeployment involved. The first thing that has to be done is LOCATING the station which is like finding a needle in a hay stack. But the coordinates of the mooring are known because they were recorded last year (always good to write stuff like that down). The next step involves essentially communicating with the mooring station's sub-surface buoy and getting the ship really close to the station. Next, communication with the release device located some 3800 meter below the surface has to be established. When everything on deck is ready to go the signal is sent to the release device for the anchor cable to be released from the anchor weights. If everything goes as planned, the big yellow sub-surface buoy bobs to the surface... and low and behold today it did!

The next step is to get a rope on the buoy itself. This involves lowering someone in a basket off the side of the ship with a tethered hook mounted to a long pole. The object of the game is to hook the hook through one large eyelets mounted on the buoy. Once that happens the retrieval can begin. First the buoy is hauled aboard and then gradually the various instruments that are positioned below the buoy are brought aboard and disconnected. For the scientists involved in those instruments, which have been sitting out for almost a year, they represent a gold mine of data. Most are very eager to get the data downloaded to see what was going on for the past twelve months.

The final step in the recovery process involves the retrieval of the 2 1/2 miles of cable which has to be wound onto cable spools and finally the hauling aboard of the cable-end floats and the release mechanisms. All the equipment is then lowered into the hold and work is begun on preparing it for redeployment in about 10-12 hours.

To a chemistry geek, one of the interesting things that returns to the surface along with all the instruments is the "sacrificial anodes". In sea water (which is an aqueous solution of several salts) corrosion of metals takes place readily because of the small electrical currents that develop as a result of the differences in reactivity of various metals. So to prevent the metals that make up the equipment and instruments from corroding, a piece of a highly reactive metal is attached to the other metals and it is allowed to corrode. This "saves" the other metals from certain chemical death. The only thing that happens in response to the sacrificial anode corroding is the deposition of dissolved metals in the sea water onto the surface of the metal surfaces of the equipment – generally not harmful to the equipment. Below is a couple of photos of sacrificial anodes retrieved from the mooring.

A sacrificial anode from a mooring shows significant corrosion while the stainless steel bolt attaching it to the frame does not.

A sacrificial anode from a mooring shows significant corrosion while the stainless steel bolt attaching it to the frame does not.

A comparison of a new zinc sacrificial anode on the left, and a used sacrificial anode on the right showing significant corrosion.

A comparison of a new zinc sacrificial anode on the left, and a used sacrificial anode on the right showing significant corrosion.

Chemistry Timeout

So there is a relationship then between carbon dioxide and pH. Since carbon dioxide can dissolve in water and then reacts with water to form carbonic acid which then dissociates and eventually forms H30+ ions, it follows that an increase in CO2 will cause a decrease in pH because the solution is getting more acidic. Since CO2 is a gas the only way to increase the concentration of CO2 dissolved in water is to first increase the concentration of CO2 in the air that is in contact with the solution. In chemistry speak we refer to it as increasing the partial pressure of CO2 (pCO2) which is the pressure that the CO2 exerts if you were to separate it from all the other gasses in the air. This is the basics behind what is known as Ocean Acidification which we'll get to next time.

Scenes From Around the Ship

Jim Ryder (WHOI) gives the mooring recovery crew a run down on the day’s events.

Jim Ryder (WHOI) gives the mooring recovery crew a run down on the day’s events.

The sub-surface buoy comes to the surface during mooring recovery.

The sub-surface buoy comes to the surface during mooring recovery.

A crew member attaches the recovery hook to the sub-surface buoy.

A crew member attaches the recovery hook to the sub-surface buoy.

The sub surface buoy is lifted out of the water along with the instruments tethered below.

The sub surface buoy is lifted out of the water along with the instruments tethered below.

Rico Amamio the ships Bosun directs the crane operator during mooring recovery.

Rico Amamio the ships Bosun directs the crane operator during mooring recovery.

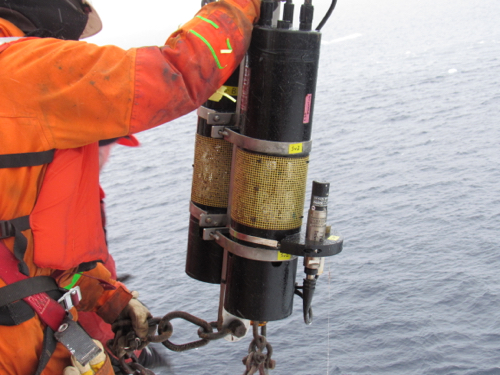

A SAMI pair is retrieved during mooring recovery.

A SAMI pair is retrieved during mooring recovery.

Mike DeGrandpre (UM) downloads the data from a SAMI after it was retrieved from a mooring in the Beaufort Sea.

Mike DeGrandpre (UM) downloads the data from a SAMI after it was retrieved from a mooring in the Beaufort Sea.

Add new comment