McMurdo is more than just a scientific research station – it's a major city on the continent of Antarctica. In fact, it's the largest city out here. Like any other city it produces its own fair share of waste which would normally go to a dump or be processed at a wastewater treatment facility. The Antarctic Treaty does not allow for a landfill, so all material waste must be flown back to the states (more on that in a future journal) but with wastewater we are allowed to just dump it into the Ross Sea with minimal treatment. To the great pride of McMurdo, we do considerably more than that with the state-of-the-art wastewater treatment facility – besides being the farthest south, it's also the most advanced down here.

McMurdo Personnel Profile

The Facility

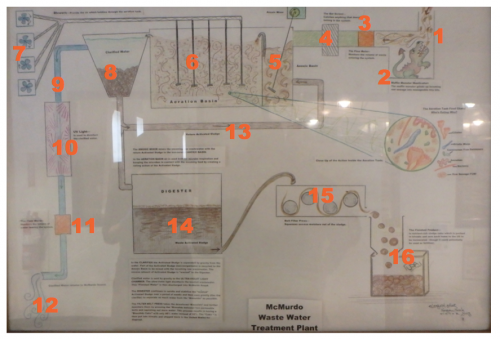

The McMurdo Wastewater Treatment Facility was built in 2003 at a cost of $XXX and currently treats all the gray water (water from showers, sinks, dishwashers, and such) and black water (water from toilets) from the station and releases it into the Ross Sea. The facility is designed to treat water to the same levels as would be expected in the mainland United States. The steps below are included on this diagram:

This diagram is at the entrance to the Wastewater Treatment Facility and provides a brief rundown of the basic processes that are at work here.

This diagram is at the entrance to the Wastewater Treatment Facility and provides a brief rundown of the basic processes that are at work here.

The Different Stages of Wastewater Treatment

Incoming wastewater from McMurdo arrives at the Wastewater Treatment Facility. Also included here are the Grinders – called muffin munchers – grind up solid waste from the different wastewater sources so that it can more easily be processed and broken down.

Incoming wastewater from McMurdo arrives at the Wastewater Treatment Facility. Also included here are the Grinders – called muffin munchers – grind up solid waste from the different wastewater sources so that it can more easily be processed and broken down.

**Step 1**: Incoming waste from all the different parts of McMurdo arrives at the facility. All waste is collected at this central location and the amount of waste varies collected varies on the time of day – there is a control computer in the front of the building that monitors every aspect of flow and makes sure that everything is running smoothly. At the intake point, there is a secondary pipe for emergency situations which would vent directly out to the ocean – this has never been used but should an emergency occur there are options.

**Step 2**: The "muffin munchers"grind up the raw sewage into tiny bits – very small bits. There are two of them in the McMurdo system designed as a backup should one of them need to be taken off line for repairs or in extreme cases of flow. The munchers basically contain multiple interlocking gear sets to grind the solid waste, as well as any other items in the waste water stream, into as small of pieces as possible.

The flow meter allows the plant manager to keep a close eye on how much wastewater is actually arriving at the plant as well as have a visual of what is flowing through.

The flow meter allows the plant manager to keep a close eye on how much wastewater is actually arriving at the plant as well as have a visual of what is flowing through.

**Step 3**: The flow meter keeps track of the volume of material arriving at the facility. Flow rate and discharge are important factors in a large number of fields and are often used in water quality measurements. Flow rate is a measurement of how fast the liquid is moving via the rate equation, and discharge is a measurement of how much material is moving past a given point in a certain amount of time. You can find out more about the discharge measurement and how to do it yourself by surfing over to the handy instructions from the US Geological Survey.

The bar screen is one of the last locations to remove large items that cannot be digested by the microbes.

The bar screen is one of the last locations to remove large items that cannot be digested by the microbes.

**Step 4**: The bar screen catches items that cannot be disposed of in the system – things like wet wipes for example cannot be broken down via the wastewater treatment facility and are captured at this point. The bar screen needs to be manually cleaned periodically (McMurdo is actually pretty good at not putting "other" items into the wastewater stream so it doesn't need to be cleaned as often as other systems), the material is then placed in a bucket and treated as a toxic waste and shipped back as is to the United States for disposal there.

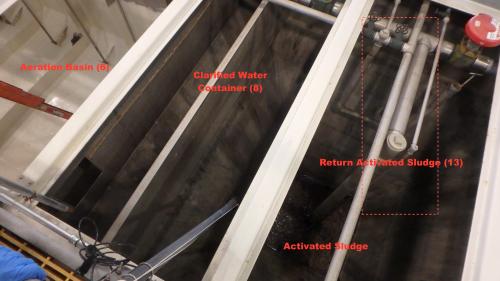

Now we have a consistent waste water stream, it is mixed with RAS in the anoxic container. Once fully mixed together the waste water flows in the Anerobic containers.

Now we have a consistent waste water stream, it is mixed with RAS in the anoxic container. Once fully mixed together the waste water flows in the Anerobic containers.

**Step 5**: Once the waste has been ground up, measured and cleaned of larger, non-organic materials, it is moved to the anoxic chamber. Here the incoming raw wastewater is mixed with the Return Activated Slug (RAS) - Step 13. Since the RAS already contains the microbes that are involved in the breakdown of the sewage, by mixing the incoming raw sewage with the RAS the process is helped along as a continuous stream. The microbes that are present are from us – the users of the system – the microbes are already in our guts and are transported with our waste. Once it's all nicely mixed together, the waste stream flows into the aeration chamber – now the real action begins.

**Step 6 and Step 7**: The blowers and compressors in Step 7 provide the air needed to mix the wastewater. In the video below you can see the middle stream of wastewater (there are three in total, one of them is offline for maintenance and the other you can see on the opposite side). Although it looks like the waste is flowing across the image, it's actually flowing in the direction of travel in the video. The

The compressors and blowers take outside air and then pump it into the aeration tanks (Step 6) – the microbes love to have some oxygen in there which encourages the digestion of the waste.

The compressors and blowers take outside air and then pump it into the aeration tanks (Step 6) – the microbes love to have some oxygen in there which encourages the digestion of the waste.

air from the blowers is being forced through a series of pipes at the bottom of the aeration tank (Step 6), those bubbles then rise and spread out making it "look" like the water is flowing opposite the way it actually is. When watching the video, take note that the amount of air from each "bubbler" is decreasing as you move down the stream – this encourages the flow of wastewater through the system while at the same time aerating the waste water for the microbes to enjoy. You can also see what is called FOG (fat, oil, grease) forming as a foam on top of the waste stream – a major source of waste water (called gray water) here in McMurdo comes from the kitchens.

Once through the aeration tank, the waste water can go one of two ways and the solid (since they have a greater density) settles to the bottom.

Once through the aeration tank, the waste water can go one of two ways and the solid (since they have a greater density) settles to the bottom.

**Step 8 and Step 9**: In the final tank in the video, the water is allowed to calm with solid material with a higher density settling to the bottom. At this point, the waste stream can flow in three different ways: as clarified water to Step 9, as RAS back to Step 5, or as solid waste to the digester (Step 14). Note in the picture the pipe near the

The clarified water slowly drains out and begins to flow via gravity to a side room where it receives one last treatment.

The clarified water slowly drains out and begins to flow via gravity to a side room where it receives one last treatment.

bottom of the pyramidal shaped tank – that pipe is taking the Raw Activated Sludge (RAS) back to Step 5 to be mixed with incoming raw wastewater. One last screen (Step 9) catches any other large materials that may have sneaked through and now the clarified water is on to its next stage.

But first ...

**Step 14**: After settling to the bottom of the clarifier, the wasted activated sludge (WAS) is sent to the digester where the it is continued to be aerated and is stabilized over the next few weeks. As this continues gravity is again used to continue separating as much water as possible from the biosolids.

**Step 15 and Step 16**: Every few weeks the dewatered biosolids are sent to the filter belt press to continue the process of dewatering by roller pressing them between two permeable belts and literally squishing more water. This process results in having a "biosolid cake" with only 86% water as opposed to 96% water. The "cake" is then packaged into a container, stored, and then shipped back to the US for disposal in a landfill in California once the port is free of ice and container ships can begin to arrive.

Once the biosolids have gone through initial dewatering in the digester, they are transferred to the belt press where they are slowly rolled between two belts and rollers until finally being ejected out the back of the press and dropped through the floor to a waiting container.

Once the biosolids have gone through initial dewatering in the digester, they are transferred to the belt press where they are slowly rolled between two belts and rollers until finally being ejected out the back of the press and dropped through the floor to a waiting container.

Okay lets get back to the other departure point ... out of the clarifier the other way ...

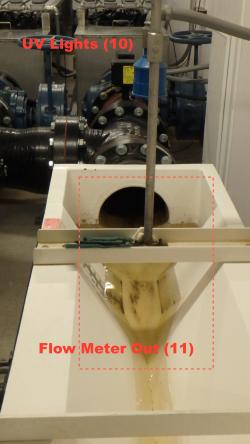

**Step 10**: A quick trip through some ultra-violet lights to disinfect the water is the last little bit of treatment that the waste gets before it is sent through another water flow meter (Step 11) to see how much is actually leaving the plant this way (remember in Step 8, the waste could go to the digester as well as going back to the front of the line via the RAS). Once the water has left the plant it is discharged into the McMurdo Sound as clean water – right where we got it from to begin with!

The clarified water passes through a set of ultra-violet lights in order to disinfect the water before discharge. As before, there are multiple sets of these so that one can be taken offline if necessary or repaired.

The clarified water passes through a set of ultra-violet lights in order to disinfect the water before discharge. As before, there are multiple sets of these so that one can be taken offline if necessary or repaired.

Before its final departure from the treatment facility, the not clarified and disinfected water passes through a final water flow rate meter. You can see the UV lights in this picture in the rear (top) of the picture).

Before its final departure from the treatment facility, the not clarified and disinfected water passes through a final water flow rate meter. You can see the UV lights in this picture in the rear (top) of the picture).

In The Field

When the team is in the field all waste (gray water, black water, solids) needs to be collected in buckets that are then stored near camp. Those buckets are then stored on base as well until a container ship arrives and that material is then shipped back as well to the US for disposal.