You have been reading this journal completely add free, but that is about to change. I am advertising a Live Event in which we will be presenting through the computer some of what has been going on the cruise. We will show slides with the pictures of the trip and talk about the science in them. The biggest benefit is that you will be able to ask us questions in real time. All you need is a computer with internet access, speakers and a microphone (or a phone, if your computer does not have a microphone). Have you ever talked on the computer or phone with scientists in the Southern Seas? This is your opportunity, Technology is amazing! All you have to do is register for the event. I hope to hear you all then. Here is the add:

Join us for the upcoming real-time PolarConnect event with PolarTREC teacher, Juan Botella, and scientists of the Seawater Property Changes in the Southern Ocean who are on board the Icebreaker N.B. Palmer of the coast of Antarctica! Participants will learn more about the oceanography of the Antarctic and how scientists are studying this unique place.

Anyone is welcome to participate: classrooms, teachers, or just interested members of the public. These events are hosted through the PolarTREC PolarConnect (formerly Live from IPY!) program, and participants will have a chance to learn from the scientists, ask questions, and chat with others during the presentation.

EVENT DETAILS

DATE: Thursday, 14 April 2011

TIME: 1:00 PM AST (2:00 PM PST, 3:00 PM MST, 4:00 PM CST, 5:00 PM EST)

Registration: To register (required, but free) and to receive instructions on how to join, go to: http://www.polartrec.com/polar-connect/register

Now back to our feature presentation:

Yesterday was another day full of excitement as we deployed a 4500m long mooring. We would have liked to deploy it on Saturday, but bad weather kept us waiting a whole day. A good deployment requires science, hand skills on deck, art and luck. We found a great balance among these ingredients in a very successful deployment. The weather was pretty good and varied. We started with light snow at 8:00 am, and by 1:00 pm we had a sunny day. Seas were pretty good for what they had been on Saturday.

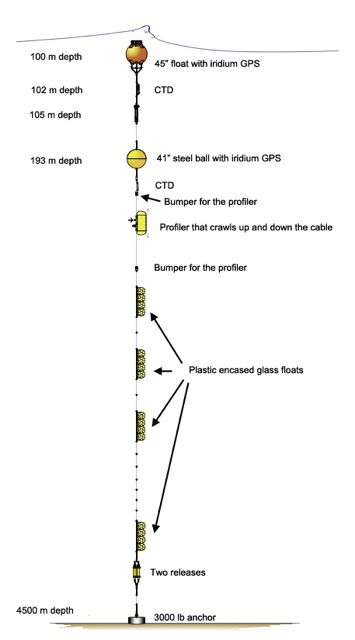

The scientist in charge of the mooring is not here on the boat. She designed the mooring to be in about 4500 m of depth with most of the instruments attached between 100 m and 200 m of depth. Jim Ryder brought all the cables, floats, heavy weight and instruments according to the plan. This means we cannot put the mooring just nearby where the scientists wants, it needs to be at a precise location at the given depth so the instruments end up being at the right depth.

Design of the mooring we deployed. This design is intended to have most of the instruments in the upper layers. There is a 1000 segment has an instrument that crawls up and down profiling the water like the CTD on the rosette.

Design of the mooring we deployed. This design is intended to have most of the instruments in the upper layers. There is a 1000 segment has an instrument that crawls up and down profiling the water like the CTD on the rosette.

Imagine we go out and deploy the mooring in an area that is actually 100 m shallower than expected. No big deal, right, 100 m out of 4500 m is a small fraction. But, if the top buoy is supposed to end at 100 m of depth, as it is the case in this mooring, and we deploy it in this shallower area, the buoy will now end up in the surface. The instrument that is supposed to be at 102 m would only be at 2 m below the surface.

The first step for a successful deployment is finding the right spot in terms of depth and where the scientist wants it. It would be great to find a large area that has that depth, so we have more margin of error, but it depends on the bathymetry, not on us. When looking at the map we found a better place for the deployment in therms of the depth a few kilometers away from where the scientist wanted it, but we cannot just decide to move it for our convenience, since she chose that particular spot based on interesting oceanographic phenomena. We spent a few hours on Saturday with our multi-beam sonar determining the exact depth at the location to be deployed. We then sent the rosette with an altimeter to precisely measure the depth at that point.

The mooring is assembled as we deploy it. I spent a few hours with Jim on Wednesday spooling the 4.5 km of cable. We needed to reel it out as we go and attach the instruments and buoys. We put the cable and instruments on the water starting from the top as soon as we attach them. The whole process takes about 7 hours.

Assembling a mooring on deck. The large orange buoy on the left is the top buoy. You can also see a couple of instruments on the floor.

Assembling a mooring on deck. The large orange buoy on the left is the top buoy. You can also see a couple of instruments on the floor.

It is not a good idea to spend the seven hours above the location for the mooring as we put overboard the cable, floats and instruments because the cable would just get tangled in a huge mess. It is better to have the ship sail very slowly so the cable aligns behind the ship like a fishing line. Remember we deploy the upper part of the mooring first, the one with the biggest floats.

This picture shows the cable coming out of the winch towards the stern. You can also see back in the water the orange float. At the end the orange float will be trailing more than 4000 m behind the ship.

This picture shows the cable coming out of the winch towards the stern. You can also see back in the water the orange float. At the end the orange float will be trailing more than 4000 m behind the ship.

The first floats kept the mooring afloat, which allowed Barry and Jim attach the instruments on the cable. Jim had placed marks on the cable where each instrument should be attached, and Alex had the diagram with him to verify everything's right placement.

Barry and Jim attaching an instrument on the line.

Barry and Jim attaching an instrument on the line.

Every now and then, at precise spots on the cable, strings of encased glass floats where placed. Here is one of those beads of floats ready to be attached to the cable. I can tell this was towards the end of the deployment by the sunny skies.

Encased glass floats ready to be deployed while the nice sun shines in the sky.

Encased glass floats ready to be deployed while the nice sun shines in the sky.

The art part comes for the timing of events. We need to begin the process far from the spot where we want the mooring to be, about 7 miles away, and sail towards this spot as we deploy the instruments. We need to time everything so when we have all the mooring out and just need to drop the heavy weight we are actually in the desired spot. It worked like a charm. Jim synchronized the whole process like magic. The heavy anchor of 3000 pounds is deployed at the end, when we have more than 4500 meters of cable floating in a straight line behind the ship with many instruments and floats attached to it. Jim said we sailed past the right spot about 300 m because the drag of the rest of the mooring pulls the weight back. It takes about an hour for the anchor to make its way to the bottom, pulling all the floats and instruments.

The heavy anchor to moor the cable is dropped at the end.

The heavy anchor to moor the cable is dropped at the end.

We did a triangulation with the ship around the mooring communicating with the transducers of the release (see March 20 entry for a description of the release and transducers), to make sure every thing is working well and to find the exact location of the landing. The anchor does not fall in a straight line; we cannot assume we know its location by the place where we dropped it. The anchor landed extremely close to where Jim wanted it to land, within less than 200 m away from the target. That was a great deployment!